Solvent Selection for a Greener Process

Are you hoping to improve the greenness of your chemical processes? There are several drivers leading companies towards adopting the green chemistry principles, which aim for waste prevention, improved process safety, increased energy efficiency and reduced health impact. New regulations as well as the beneficial reduced cost associated with a greener process, are two key motivators.

Good process development should naturally lead to greener chemical processes with fewer chemical steps, higher yields, and reduced waste. DoE is a powerful tool for reaction screening and optimisation although many who use it limit its potential by just looking at standard reaction conditions such as temperature, concentration or reaction stoichiometries. When used in combination with Principal Component Analysis (PCA), DoE can be used to screen reaction solvents at the same time as quantitative factors. The role of a solvent is complex and it is often not a simple task to find a solvent which facilitates a high yielding process that is also defined as ‘green’. Additionally, solvents can have an effect on reaction pathways, can avoid side reactions, affect engineering issues such as mass transfer and viscosity, and affect work ups.

The best solvent for your reaction may not be the greenest in terms of health, safety, or environmental ratings, but that which allows a direct telescope to the next step, allows direct isolation of the product, or can be recycled in existing plant infrastructure. Any of these will increase the green rating of a process, however you choose to measure that (PMI, e-factor, GAL etc).

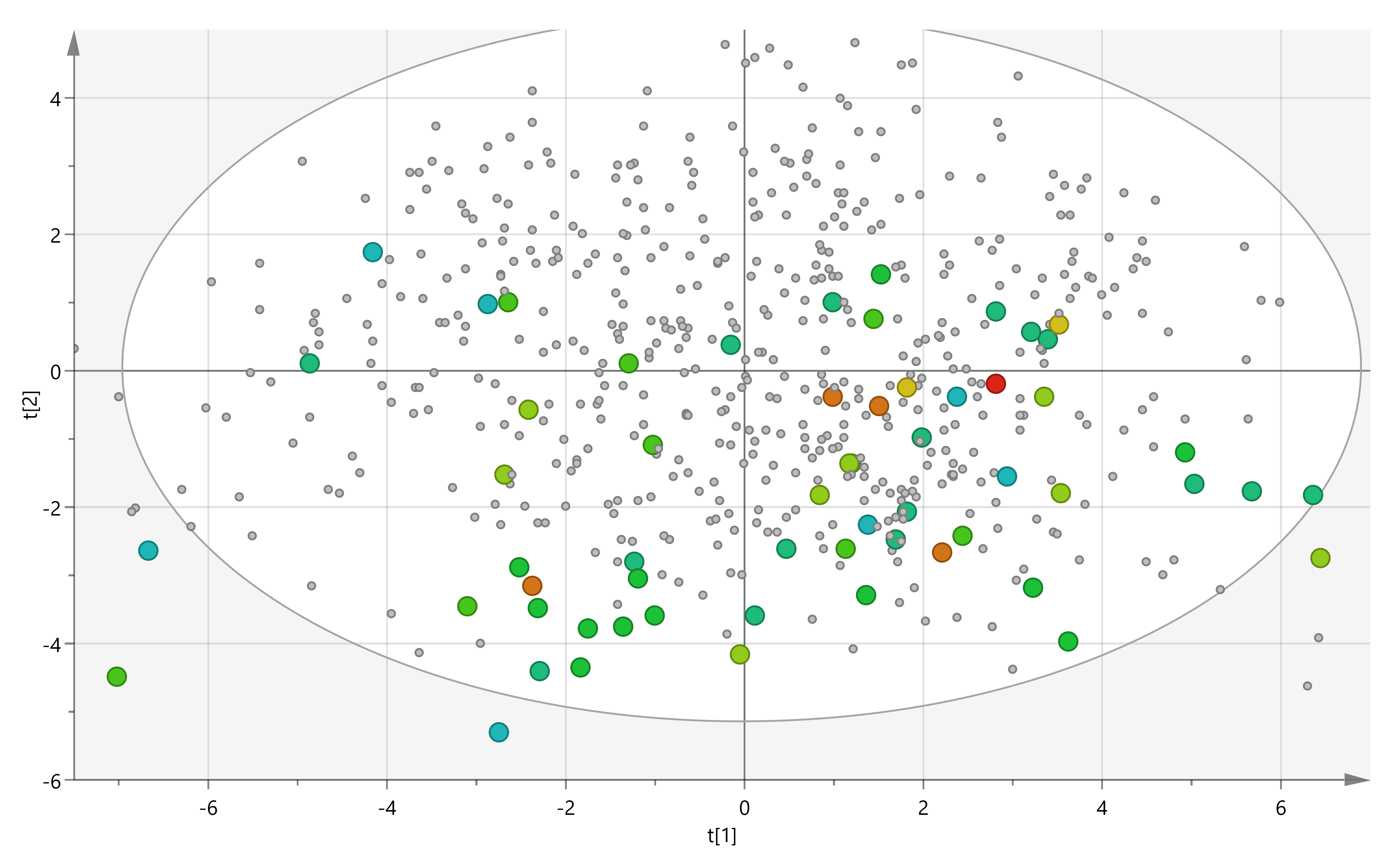

Using advanced DoE with PCA will allow you to screen a range of diverse solvents with varying properties and identify the best area of solvent space for your chemistry on a solvent map. We can identify areas of activity on the map and the solvents within this region should all perform well, chemical incompatibility aside. From our solvent database of over 2000 solvents, including green, bio-based and bio-renewable solvents, there will be several options within the area of activity and the most appropriate solvent for the process can be chosen from this selection. This process enables informed decisions to be made, giving you a choice from solvents which may have different physical properties or a process related benefit. It is also important to remember the optimum conditions for a process with one solvent will probably be somewhat different with another solvent, so doing this in conjunction with experimental design is preferred.

Above: A solvent map showing a selection of the solvents from our database in grey. The colour coded dots represent the health rating of some solvents, where blue is low impact and red is high impact. Our solvent database contains over 2000 solvent with many chemical and physical properties, including the health, safety and environmental ratings of many of the common lab solvents.

In summary, using DoE in combination with PCA is an effective tool for improving the greenness of a chemical process. Our approach optimises the experimental conditions and finds the area of solvent space where the experiment performs best, allowing an intelligent selection of solvent, considering sustainability, cost, ICH/REACH regulations, availability or any other driver, as the process is optimised.